What are the functional characteristics of melt gear pumps for HDPE materials?

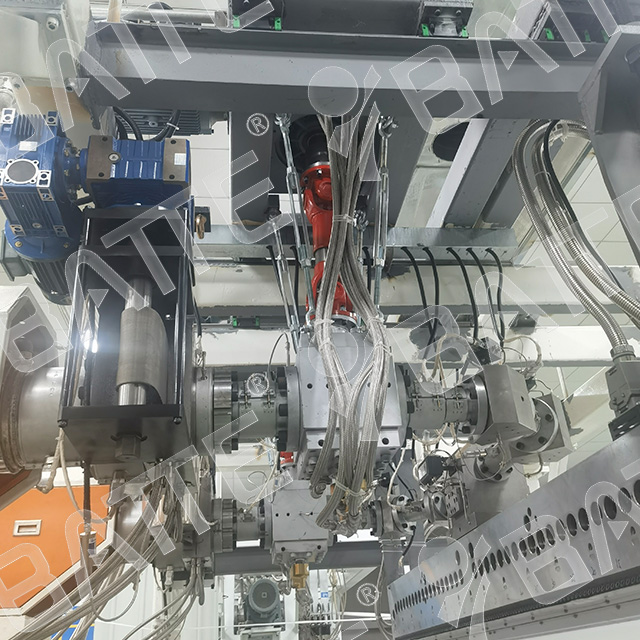

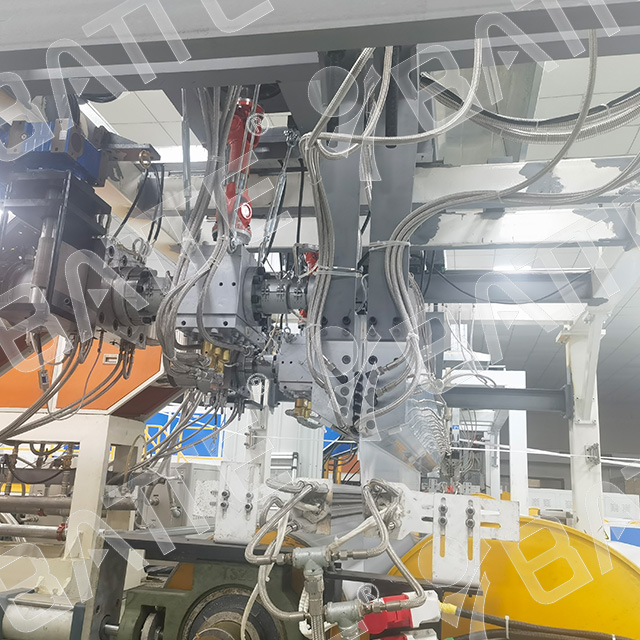

In HDPE extrusion processing lines, melt pumps are typically installed between the screen changer and the die head for metering, pressure boosting, and pressure stabilization. When using a gear pump, a heating source must be provided on the pump body to raise its temperature from room temperature to within the range of 180°C to 230°C, allowing the material to melt before starting the pump. Once power is supplied and the gear shaft begins to rotate, it starts pumping the material. As the gear shaft rotates, the material inside the pump casing is squeezed and sheared by the gears. During the shearing process, the material itself releases a significant amount of shear heat, which disrupts the thermal balance of the pump body, causing it to rapidly heat up within a short period and exceed the process temperature of the material, thereby affecting its quality. Additionally, the amount of shear heat varies with the rotational speed of the gear pump, a characteristic that further complicates temperature control. Therefore, melt gear pumps for HDPE materials need to fulfill the following functions: they must be able to both heat up and intelligently cool down.

Specialized melt gear pumps for HDPE materials cool the driving and driven shafts through cooling water flowing through rotating joints. Simultaneously, the cooling water flows through the pump casing via the upper gland to cool it down and subsequently cool the material. The pump casing can also be heated using electric heating rods. The electric heating rods and cooling water are controlled by a PID system, realizing intelligent temperature control. This replaces the traditional mold temperature control machine scheme, reducing maintenance and operating costs, lowering safety risks during personnel operation, and enabling intelligent temperature control to improve product quality. Zhengzhou Bate offers melt gear pumps with specifications ranging from 0.1CC to 12000CC. For more details, you can consult our 24/7 service hotline.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071